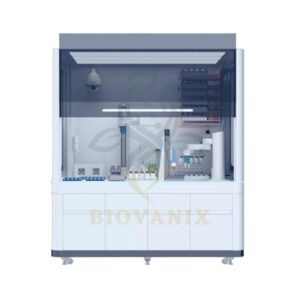

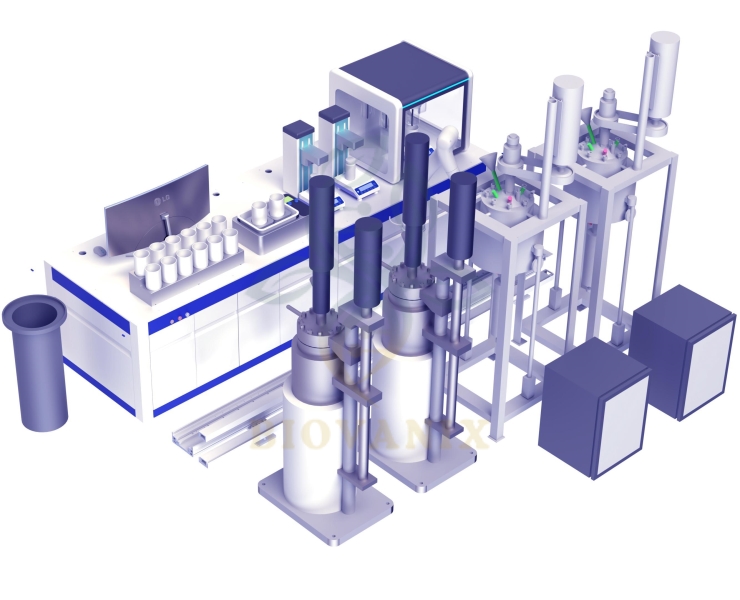

Intelligent Pharmaceutical Synthesis/Detection Platform

Introducing Biovanix Intelligent Pharmaceutical Synthesis & Detection Platform, designed to redefine efficiency and precision in your research. This comprehensive platform automates the entire experimental workflow, from initial preparation to final data logging, ensuring unparalleled accuracy and reproducibility.

Core Features & Automation:

Automated Workflow: Our system integrates key laboratory processes, including automated weighing, sampling, reaction, drying, and data entry, eliminating manual intervention and human error.

Seamless Equipment Integration: The system seamlessly interfaces with a wide range of essential lab equipment, such as balances, fluid pumps, autosamplers, ovens, reactors, centrifuges, gas chromatographs (GC), and liquid chromatographs (LC).

High Intelligence & Precision: Powered by intelligent control algorithms, the system operates with a high degree of automation, guaranteeing precise execution and consistently accurate results.

Biovanix intelligent system is more than just a collection of automated devices; it is a unified solution that streamlines your entire research process, allowing your team to focus on analysis and innovation rather than repetitive manual tasks. With its high level of intelligence and proven accuracy, it’s the next step in laboratory automation.

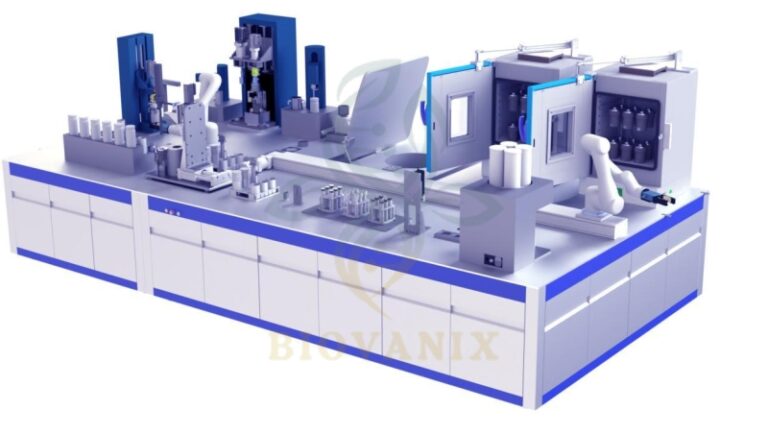

Ai Driven Engine & Modular Equipment Matrix

AI assists with scientific thinking, while robots undertake experiments, freeing up scientists from tedious and repetitive desk and experimental work.

The company’s research is centred on the flexible intelligent track of life sciences, with the objective of constructing a modular equipment matrix and a “building-block” software-hardware collaborative ecosystem with AI middleware as the technical core. It is evident that the systems architecture has been meticulously designed to address the evolving requirements of experimental R&D, thereby facilitating the efficient execution of complex tasks and labour-intensive operations. This is achieved through the implementation of flexible departments. The system’s wide range of applications extends to fields such as life sciences, biological preparation, drug development, applied chemistry, and analytical detection. This adaptable and scalable solution offers significant advantages in these and other domains.

Core Features & Automation

7*24 hour automated synthesis

Thanks to the coordination of robotic arms, automated equipment and an intelligent scheduling system, the laboratory can operate unattended 24/7, overcoming the limitations of manpower and time.

AI autonomous parameter adjustment

The AI model dynamically optimises the core parameters of the formula based on detection and analysis data, forming an intelligent closed loop of experiment, analysis and optimisation.

High-throughput parallel synthesis and screening

Based on robotic arm cluster technology, it enables the simultaneous synthesis and screening of various compounds, exponentially increases experimental throughput and improves single-batch processing capacity by 5-10 times compared to manual operation. This allows a large number of candidate solutions to be covered quickly.

Automatic evaluation and analysis of synthetic

products Integrated XRD, spectral analysis and mass spectrometry, as well as other automated instruments, can analyse the core data of compounds in real time to enable autonomous parameter adjustment by AI.

Flexible Combination For Various Scenarios

Cell

Therapy

Synthetic

Biology

Biological Fermentation

Pharmaceutical Screening

Synthesis of Compounds

Program-free Operation Control System

Combined Instruments

- Mass Spectrometer

- Nucleic Acid

- Extraction

- Cell Counter

- Microplate Reader

- High-Content

- Imaging System

- Biological Safety

- Cabinet

- Cell Disruptor

- Laminar Flow Hood

Self-developed Products

Integrated Standard Instruments

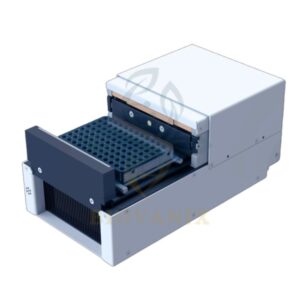

- Automated Consumables Storage Rack

- Sealing Machine

- Film Peeling Machine

- Centrifuge

- CO₂ Incubator

- PCR Amplifier

- Microplate Reader

- Cell Imager

- Washer

- Constant Temperature Shaker Incubator

- Multi-Position Shaker

- Fully Automated CO₂ Shaker Incubator

Liquid Handling & Robotics

- 8-Channel Liquid Handling Workstation

- Automated Liquid Dispensing System

- High-Throughput Cell Dispenser Workstation

- Fully Automated Cell Culture Flask Workstation

- Intelligent Media Dispenser System

Cell & Molecular Biology

- Intelligent Cell Line Screening Automation System

- Fully Automated Cell Transfection Workstation

- qPCR Pre-processing System

- Plasmid Construction System

- Intelligent DNA Automated Assembly System

Microbial & Protein Testing

- Intelligent Microbial Plate Coating System

- Intelligent Enzyme-Linked Immunosorbent Assay (ELISA) Automation System

- Fully Automated Protein Purification Workstation

- High-Throughput Screening for Enzyme Engineering

Medicine Screening

- High Content Screening

Self-developed modules and integrated equipment have the ability to design and integrate hardware instruments, building technical barriers

Biovanix Information has developed a comprehensive system of solutions for the rapid construction of automated laboratories, leveraging its automated control platform and Industrial Internet of Things (IIoT) technology. The system integrates proprietary control and drive technologies for specialised instruments used in cell research, biological experiments, materials science and chemical production. This framework significantly shortens project delivery cycles and optimises profit margins, establishing robust cost advantages and creating technological barriers in industry competition.

Sample storage

Weighed on a scale

Switching console workstation

Ultraviolet spectrometer

Powder discharge

Pipetting Workstation

Suction station

Gas chromatography workstation

Liquid discharge

Liquid workstations

PCR experimental workstation

Clinical diagnostic workstation

Mix the powder and liquid

Centrifugation work station

XRD work station

Research workstation

Magnetic stirring

Baking oven station

ICP work station

Synthetic biology workstation

Schematic Diagram of Life Science Automation Laboratory

Automated Catalyst Preparation Laboratory

Laboratory for Catalyst Synthesis & Preparation

Automatic Hydrothermal SynthesisLaboratory

Catalyst Synthesis Laboratory

Self-developed Standard Equipment

Equipment Management System

- This system enables the precise operation and activation of various instruments and devices, simplifying equipment integration and management. It also provides real-time monitoring to ensure optimal performance at all times.

Intelligent Task Scheduling System

- Dynamically allocates equipment resources based on actual demand. For multiple research projects, it analyses task priorities and equipment utilisation in real time, automatically adjusting allocation plans to enhance efficiency and scientific output.

Robotic Arm Control System

- This system uses modular programming to eliminate the need for traditional complex coding methods. Researchers can easily manage robotic arm positions and trajectories without in-depth programming knowledge, enabling them to complete programming tasks quickly and freeing up more time for experiments.

Experiment Design and Execution Platform

- It provides researchers with a visual, convenient and flexible interface for designing experimental workflows. Previously, modifying experimental procedures required costly and time-consuming secondary development by specialists. Now, however, researchers can optimise and adjust workflows at any time based on practical needs and creative ideas, freely exploring the unknown and unleashing their creativity and imagination to unlock greater possibilities for scientific research.

Automatic Pipetting Workstation

Pipette Tip

Pipette Tip 유형 | 볼륨 | CV |

50μL | 1μL | <9% |

| 200μL | 10μL | <2% |

1000μL | 1000μL | <1% |

- One-time use pipette tips: 50, 200, 1000 (tip available in microliter size)

- Volumetric pipette specifications: 500, 1000

- Claw: Optional with or without claw

- Mechanical arm: Optional configuration

Robotic Arm

Flexible and independent 8 channels, each channel can perform unequal volume pipetting, independent Z-axis movement, liquid level sensing, and span Y-axis movement, making it easy to perform pipetting operations on experimental vessels such as tubes, microplates, deep well plates, trays, and small bottles.

Anti-Droplet Technology

When transferring volatile liquids, anti-droplet technology compensates for pressure changes in the channel to prevent the formation of liquid droplets due to pressure fluctuations.

애플리케이션

- PCR/qPCR

- Protein Purification NGS

- Nucleic Acid Extraction

- ELISA

- Sanger Sequencing

- Concentration

- Uniformization

- Continuous Gradient

- Dilution

Biovanix Automatic Liquid & Powder Sample Preparation System is a high-end automated device specifically designed for laboratory settings, dedicated to achieving precise automatic weighing and dispensing of powder and liquid samples. This equipment deeply integrates cutting-edge automation technology, high-precision control systems, and a user-friendly interface, effectively mitigating human-induced errors and significantly enhancing the repeatability and reliability of experimental results.

- Ultra-High Precision, Reliable Data

- High Automation, Doubled Efficiency

- Exceptional Flexibility, Wide Compatibility

Application Area

- Chemistry

- Biology

- Pharmaceuticals

- Sample pretreatment

- Materials science

매개변수

Basic Information

Function | Specification |

차원 | 1400mm × 750mm × 750mm (subject to actual measurements) |

Tray Capacity | 8 trays |

Single Tray Capacity | 6 / 12 / 24 containers (depending on container specifications) |

Maximum Sample Processing Throughput | 192 samples |

Vibratory Feeder Stations | 2 stations |

Power Supply | 220V 800W |

Powder Treatment

Function | Specification |

Number of Powder Materials | 12 types |

Material Hopper Volume | 40ml |

Compatible Target Container Types | 2ml, 8ml, 20ml glass vials |

Solid Sample Weight Range | 1mg-20g |

Weighing Resolution | 0.1mg |

Dosing Accuracy | ±0.3mg |

Liquid Treatment

Function | Specification |

Number of liquid reagents | 12 types |

Reagent reservoir volume | 40ml |

Compatible target container types | 6ml, 10ml, 15ml, 20ml reagent tubes |

Liquid dispensing volume range | 10μl-10ml |

Liquid dispensing accuracy | ±1% |

Container Specification

유형 | Specification (mI) | Outer Diameter (mm) | 높이 (mm) | Single Pallet Loading Capacity |

Powder Container | 2 | 16 | 34 | 24 |

8 | 16 | 61 | 12 | |

20 | 27 | 57 | 6 | |

Liquid Container | 6 | 12 | 75 | 24 |

10 | 12 | 100 | 24 | |

15 | 15 | 100 | 24 | |

20 | 15 | 150 | 12 |

왜 우리를 선택해야 할까요?

Biovanix: Your Partner in Pharmaceutical Synthesis & Detect System

바이오바닉스는 기업 및 연구소의 고유한 요구에 맞춘 최첨단 세관 제약 및 화학 합성 시스템을 전문적으로 제공합니다. 당사의 사명은 합성 프로세스를 간소화하고 효율성과 정밀성을 보장하는 혁신적인 솔루션을 제공하여 과학 발전에 힘을 실어주는 것입니다.

맞춤형 설계 시스템: 당사의 전문가 팀은 고객과 긴밀히 협력하여 고객의 구체적인 요구 사항을 파악하고 연구 목표와 생산 요구 사항에 완벽하게 부합하는 시스템을 설계 및 제작합니다.

품질과 신뢰성: 소니는 합성 시스템 개발의 모든 단계에서 품질을 우선시하여 업계 최고 수준의 표준을 충족하는 신뢰할 수 있는 고성능 장비를 제공합니다.

최전선의 혁신: 바이오바닉스는 기술 발전의 최전선에 서서 최신 혁신 기술을 시스템에 통합하여 제약 및 화학 연구 분야에서 우위를 점할 수 있도록 지원합니다.

종합적인 지원: 저희의 약속은 판매 이후에도 계속됩니다. 교육, 유지보수, 지속적인 업데이트를 포함한 종합적인 지원을 제공하여 시스템을 최상의 성능으로 유지합니다.

성장을 위한 파트너십: 당사는 고객을 파트너로 생각하며, 당사의 성장은 고객의 성장과 밀접하게 연관되어 있습니다. 바이오바닉스는 개념에서 상용화에 이르는 여정을 지원하며 상호 성공을 위한 협업 환경을 조성하기 위해 최선을 다하고 있습니다.

제약 및 화학 합성 분야에서 혁신과 맞춤화가 만나는 바이오바닉스에 오신 것을 환영합니다. 과학의 미래를 함께 만들어 갑시다.