Precision Back Pressure Valve

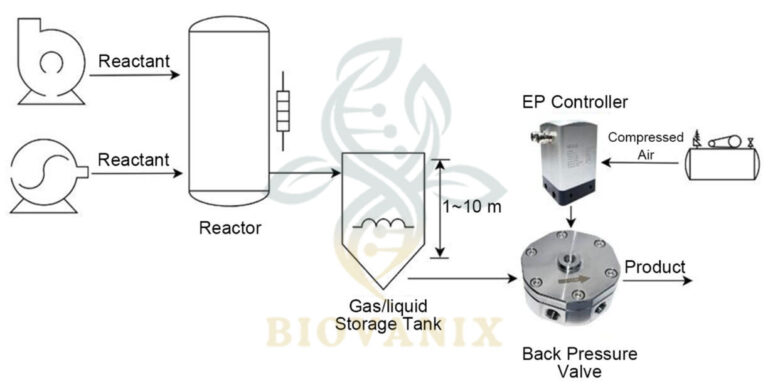

BPV Precision Back Pressure Valve is a pneumatically actuated back pressure valve designed for simplified operation. By applying a pressure equivalent to the target back pressure value to the pilot port, the valve is instantly set. This pressure forces the flexible diaphragm downward onto the orifice plate, creating a seal. Rising inlet pressure lifts the diaphragm to release excess pressure through the outlet, while a drop in inlet pressure pushes the diaphragm closer to the orifice, restricting flow and restoring pressure equilibrium.

Avantage

- Frictionless diaphragm eliminates hysteresis, achieves 3x higher accuracy and <10ms response.

- Stable pilot pressure (<0.05% FS fluctuation) and diaphragm deformation algorithm ensure ≤±0.1% setpoint deviation.

- Typical Use: Microfluidic chip pressure supply, mRNA vaccine chromatography column control.

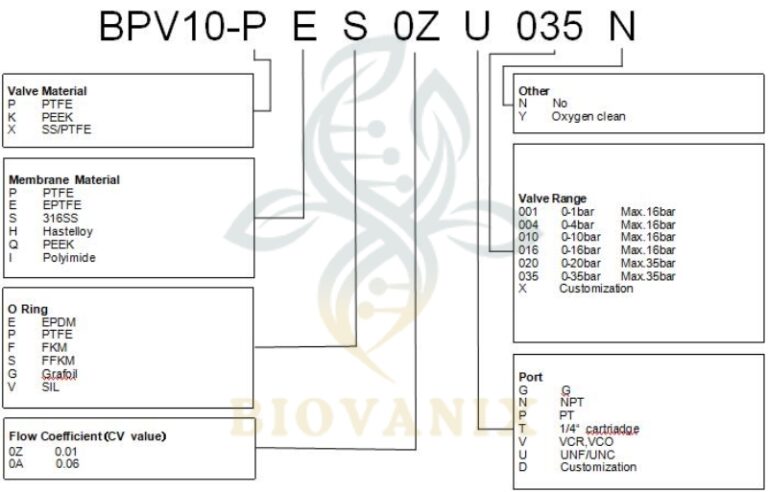

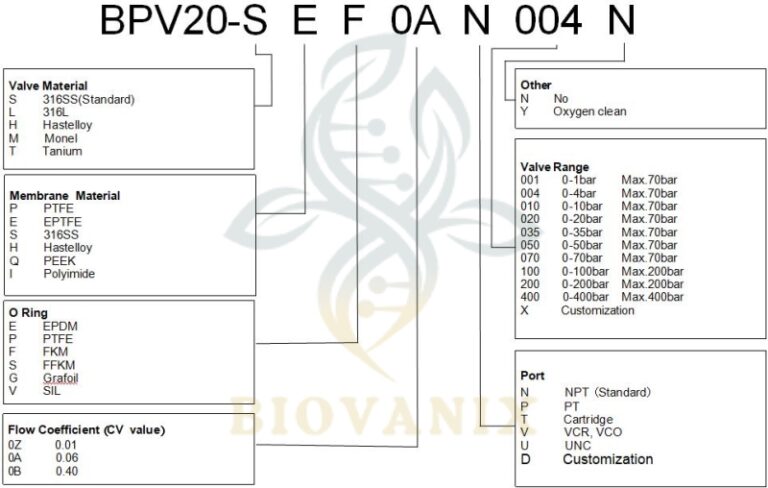

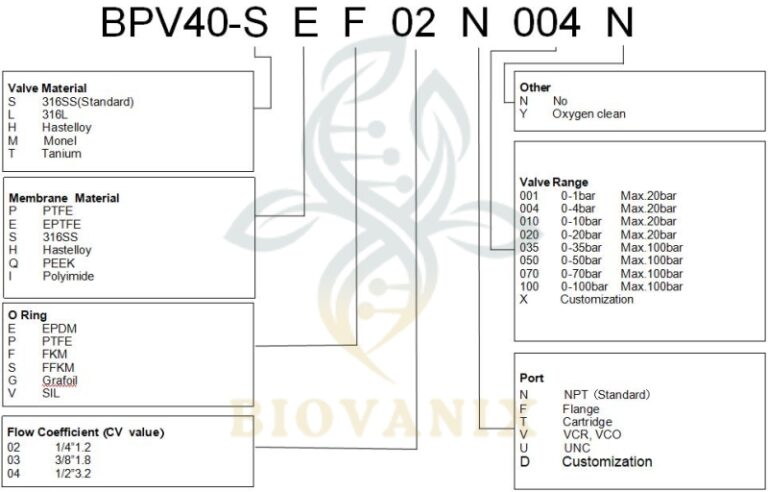

BPV-10 | BPV-20 | BPV-40/60/80 |

Construction: Monolithic PTFE/PEEK hybrid body eliminates metal contact, resistant to mixed acids (e.g., HNO3/H2SO4/HCl blends), halogens, and aggressive oxidizers.

Performance: Flow range 0.1-50 mL/min, pressure rating 1000 bar, ±0.2% FS control accuracy for dynamic pressure stabilization in microreactors and nitration/chlorination sampling.

Applications: Corrosive gas chromatography injection pressure buffering Overpressure protection in lithium battery electrolyte synthesis | Caractéristiques principales: Optimized flow path enables 0.5-200 mL/min flow control with 800 bar rating, 316L stainless steel/PCTFE seals compliant with ISO 17025.

Innovation: Integrated temperature compensation maintains ±0.5% setpoint stability from -20°C to 150°C, eliminating thermal drift in exothermic reactions.

Typical Applications: H2 circuit pressure regulation in fuel cell test stands Closed-loop pressure control for pharmaceutical CSTR | Revolutionary Design: Springless/actuator-free static pneumatic control: 0.2-10 bar air signal regulates 0-600 bar with ±0.1% FS linearity Optional I/P transducer expands signal range (4-20mA/0-10V) for SCADA integration

Cost Efficiency: Modular design reduces maintenance (MTBF >100,000 hrs) Compatible with manual fine-tuning (0.01 bar resolution) and automated modes

Industrial Applications: Flare gas pressure balancing in petrochemical plants Exhaust backpressure management in semiconductor vacuum chambers |

Application

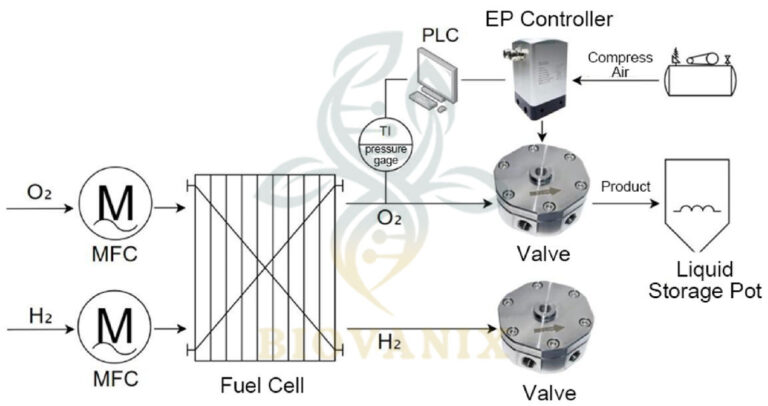

Fuel Cell Test Bench

- Extra wide adjustable back pressure valve ratio up to 1000:1.

- Handles two-phase gas-liquid media with stable pressure fluctuations.

- The controller outputs a set value to the backpressure valve, providing high-precision pressure control of the gas system.

- The back pressure valve can accurately control the outlet pressure of the power reactor by open-loop control.

- The pressure regulator can provide low pressure high precision control pressure for fuel cell test system, the accuracy can be higher than 0.5kpa.

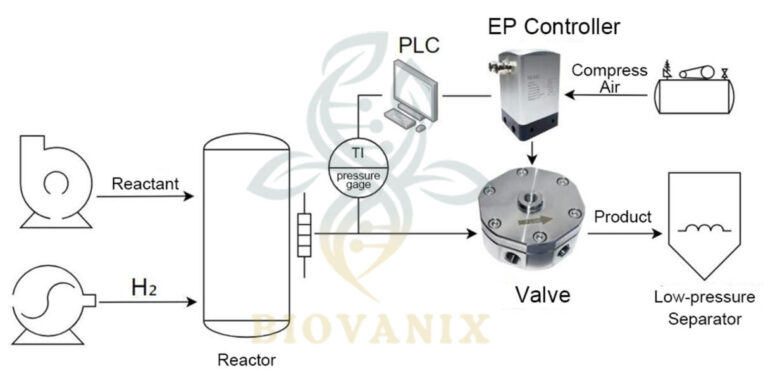

Hydrogenation Reactor

- Hydrogenation plants typically operate at high temperatures and pressures, and back pressure valves can be used up to 400 bar and 300°C. The pressure regulator sets the 1:1 pilot pressure for the back pressure valve.

- Pressure regulators set the pilot pressure for 1:1 backpressure valves.

- The structure of the back pressure valve is porous and diaphragm, no need for high-pressure gas-liquid separator, can be used directly for gas-liquid two-phase flow media, in the product back end to do the low-pressure separator tank or liquid storage tank can be.

- Diaphragm control pressure, can instantly adjust the pressure, timely to avoid overpressure, large adjustable ratio, can adapt to different flow conditions, compact appearance and gas pressure control, can do the whole back pressure valve insulation treatment to maintain accurate temperature control.

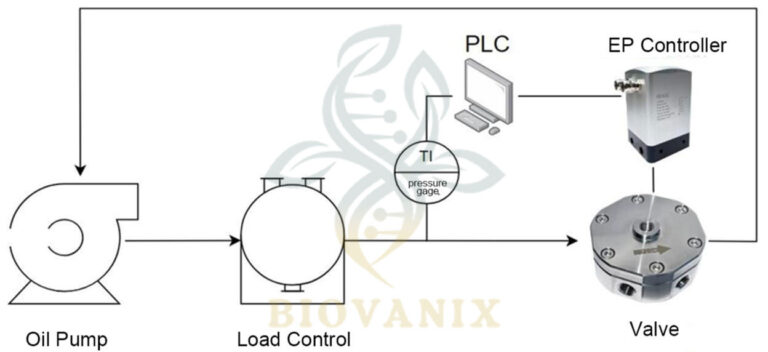

Oil Pump/Injector Load Test System

- In-line load development and quality testing.

- Ultra-wide 1000:1 adjustable back pressure valve ratio provides constant and continuously varying back pressure.

- The controller outputs setpoints to the backpressure valves for high-precision gas system pressure control.

- With constantly changing system speeds during testing, the backpressure valve can be quickly adjusted for short periods of high cycle time.

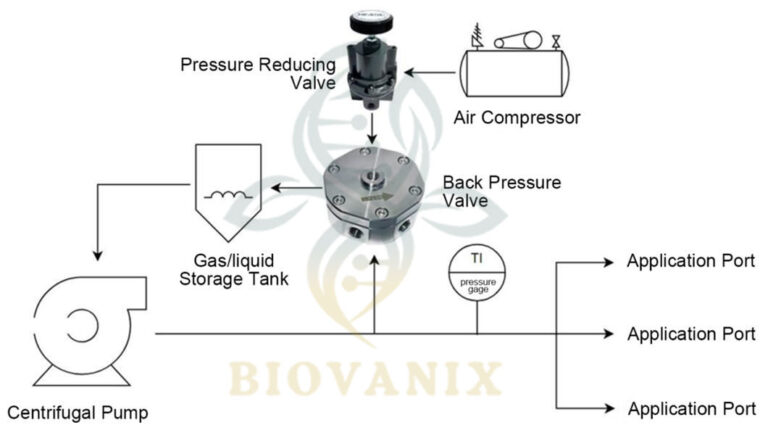

Pump Discharge Pressure Stabilization Control

- Centrifugal pumps, turbine pumps, etc., can have backflow or air intake problems in the discharge piping and pressure fluctuations can be large.

- The Back Pressure Valve creates a bypass in the piping to precisely control the pressure discharge from the pump by 1:1 pilot air control.

- The back pressure valve takes the fluctuating pressure in the piping and returns the excess pressure gas or liquid phase to the storage tank and back to the control pump via pilot air control.

Liquid Level Control

- It can provide open loop level control without complex PID loop and level sensor, sensitive and space saving.

- Closed loop PID control with level sensor is possible.

- Under low flow conditions, Mome back pressure valves can achieve an adjustable ratio of 1000:1, which is higher than traditional control valves.

- Resistant to corrosive media and high temperature up to 300℃.